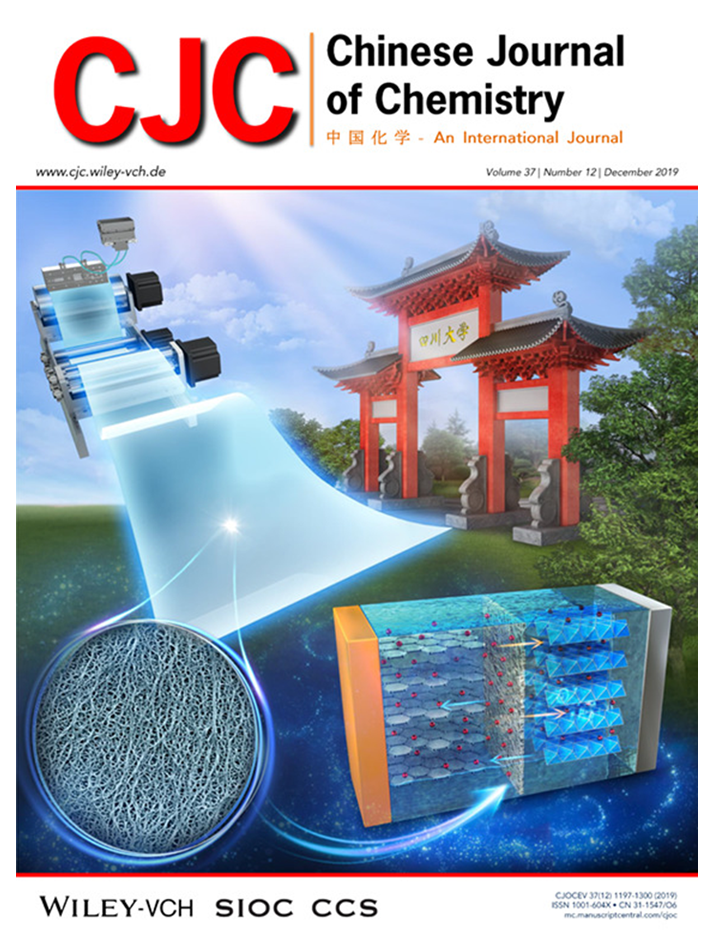

The lithium‐ion batteries (LIBs) have been widely used in the world since the first introduction in 1991. The microporous polyolefin separator is the key component to determine the electrical properties and safety of LIBs. In China, the LIBs separators were completely imported and expensive before 2008. We have realized the industrialization of LIBs separators by either dry or wet process successfully. Nowadays, China has become the biggest manufacturing country of LIBs separators in the world and the price is very much reduced. Among the separator processing techniques, the dry process based on biaxial stretching β nucleated polypropylene (β‐iPP) was originated from China and has the lowest manufacturing cost. However, the separator produced by this method has non‐uniform pore size distribution which limits its wider application. In this article, based on the better understanding of original crystal morphology on the pore formation during stretching, we present our recent works to improve the performance of dry process separator through the preparation of β‐spherulites, casting technique optimization, improved annealing treatment and multi‐stages longitudinal stretching. As a result, we produced the dry process separator with much more uniform pore size distribution than that made from the traditional dry process.

原文连接

https://onlinelibrary.wiley.com/doi/10.1002/cjoc.201990121